A spacer is needed for the bracket holding the clutch release… we fitted it all together first to get the correct distance required for the spacer and get the position of the brackets correct.

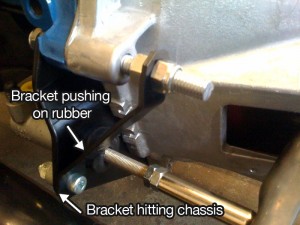

We then found that the edge of braket and the outer bolt for slave cylinder was very close to the chassis. So we ground down the edge of the brackets to match the edges of the slave cylinder, just to prevent it from hitting if the engine kicked. Also the second part of the braket was pushing in on the rubber of the slave cylinder so to stop this from happening we also ground it away slightly to give it better clearance.

We disassembled it all, repainted the brakets after grinding them and then got to work making the spacer from a piece of aluminium on Uncle Dave’s lathe. Then reassembled again with spacer and then finally connected the pipe.

–

Job done.

Leave A Comment