We had a few small jobs to get done to finish of the rolling chassis.

—

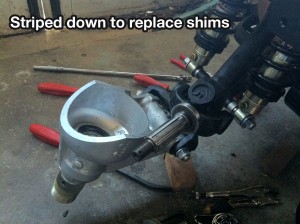

1. Change the Rear Axle shims

We realised once we got the wheels on the chassis, that there was too much play in the rear wheel baring. After removing the wheels to measure the end float we discovered the original shims we put in when building the axle back in February (read here) were 0.009 ” too big. So we striped the rear hubs to replace the shim, giving a final end float between 0.001- 0.003

—

—

2. Prop shaft safety loop installed

I’d received the prop shaft safety hoop from Gerry so we thought we’d fit that. It comes in two parts. The support bracket bolts to the chassis with 2 bolts, then four holes need to be marked up and drilled so the hoop can then be bolted to the support bracket.

—

—

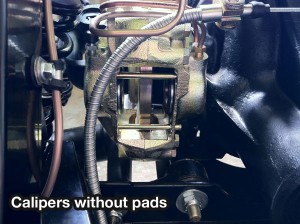

3. Fitting Rear brake pads

We had the rear pads to put in. This is a fairly simple job. We painted a layer of copper grease on the rear side, this to prevent brake squeal. Then took the retaining pins out to slide the pads into the rear calipers and then secure again with the retaining pins.

—

Leave A Comment