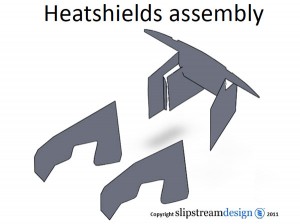

The metal cladding heatshields for the engine bay is something we’ve been working on for some time. Fortunately we have brother in law Phil Wilson who has an engineering, design and CAD (computer aided design) company in Leeds called Slipstream Design. They specialise in CAD engineering projects and prototyping of all shapes and sizes and following a conversation with Phil one weekend, we thought it would be amazing to design up exact CAD specs of the heatshields and get them manufactured via laser cutting engineering making them a perfect fit for the Hawks Cobra 289 body.

Mark being a super perfectionist and having an eye for the details, this idea really appealed as it felt a bit like we have brought a small amount of amazing F1 style precision technology and engineering to our Cobra 289.

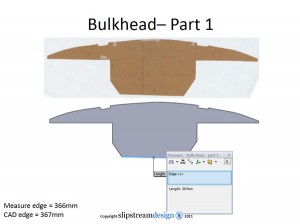

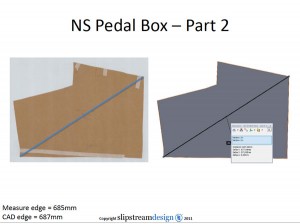

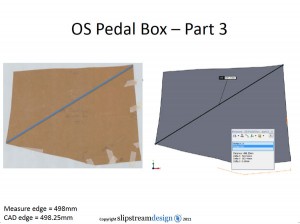

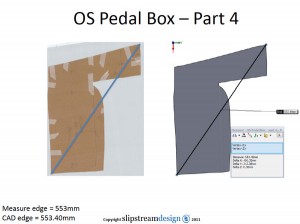

It all started in a more low tech way with me and Mark both working up rough paper templates directly from the Cobra engine bay. We then sent these off to Dale at Slipstream Design to translate onto the computer and produce and exact specs requirements. He then sent us back the drawings which Mark could print full size at work to recheck against the Cobra body. We had to go through this process a few times with minor tweaks and changes.

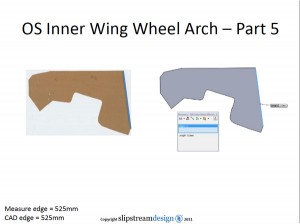

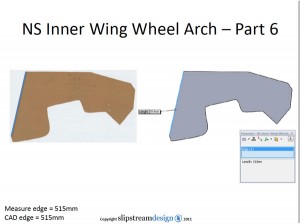

We originally planned the inner wing sections to only fit the inner plain of the engine bay, as you can see from the visuals below. However, after inspecting Andy Gordons FIA Cobra at the Silverstone show back in August, we decided to make alterations to these panels to fit them nicely round the corner of the wheel arches. More on this in the next post.

Leave A Comment