As we had decided to adapt the lower bracket for the throttle linkage mechanism back on 20th April (link to post), Mark had polished the bracket up so it was ready to fit a final time. It had occurred to us that it might be best to do a few other modifications at this point, just to increase the overall strength of the linkage system.

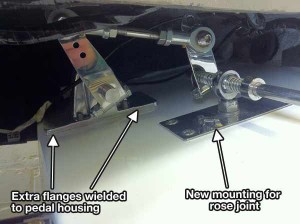

Firstly Mark decided to weld 2 extra flanges to the throttle pedal housing while also using a square plate underneath to sandwich the fibre glass. This will divert the pressure away from the heads of the bolts to help stop creaking or worse the bolts ripping through the fibre glass.

The second addition was to strengthen the position of the rose joint on the top of the footwell. Originally we had just drilled and secured this through the top of the footwell. Again we thought there was still potential for a small amount of movement due to the flex of the fibreglass. To help stop this flexing and any potential of the bolt ripping out, we made 2 rectangular plates to fix above and below (inside the footwell), again to sandwich the fibreglass and spreading the load and making it all more rigid. This in turn will give a more responsive pedal as there will be less flex and movement in the top of the pedal box.

Firstly we cut the pieces and mounted for the position, then spent some time polishing up before doing the final fit. At this stage we had 2 polishing wheels on the go in the shed so while we were at it we also decided to polish up the throttle housing as well. Even through this sits under the wing, its nice to get everything nice and shiny.

—

Leave A Comment