In order to fit the new clutch release it meant us taking out the gear box. So we got to it, unbolting the prop shaft, and the 4 front bolts that bolted the gearbox to the bell housing. With the gearbox out we could then go about fitting the new bearing.

—

—

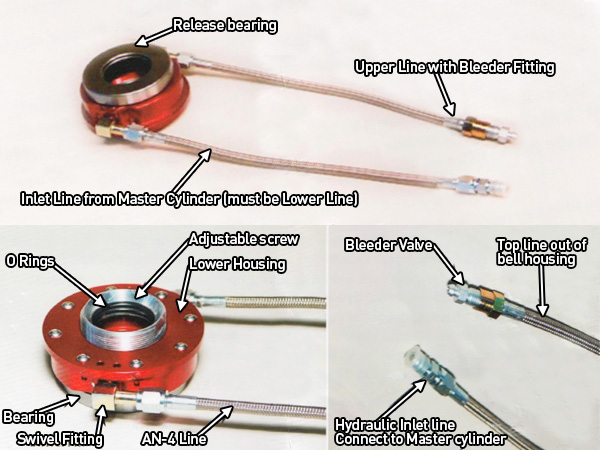

Fitting the McLeod Hydraulic Throw-Out Bearing

—

—

Step1:

You must screw the “Adjusting screw” all the way into the bearing assembly. We then slipped the bearing assembly onto the input shaft collar on the transmission. Be sure the tapered side of the adjusting screw goes on the transmission collar to sit against the base of the collar. The bearing should fit tight.

Step2:

There are two important measurement that need to be taken to make sure the bearing is fitted correctly and has enough clearance.

—

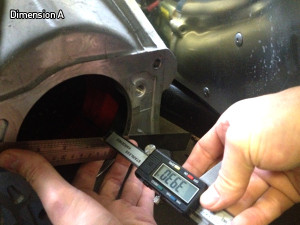

Dimension A: With the bell housing, flywheel,disc and pressure plate bolted to the engine, measure the distance from the rear surface of the bell housing to the top of the release fingers on the pressure plate.

Dimension B: Measure from the front of the transmission to the front face of the release bearing.

—

—

You then have to subtract “Dimension B” from “Dimension A”. This will give the clearance from the bearing to self adjust. The total allowable clearance should be between 0.100″ and 0.150″. You can adjust the distance by screwing out the bearing until the proper clearance is achieved. One complete turn will provide 0.06″ movement forward. There is also an extra spacer that comes with the kit which you can use if required to make the clearance. We found that using the spacer with one turn of the the bearing gave us a clearance of 0.123″ which was perfect.

—

Leave A Comment