Once the new bearing was measured and fitted correctly it was then a case of reinstalling the transmission and connecting back to the bell housing.

—

Important point is always have the AN-4 line with the bleeder valve at the top when the bearing is properly adjusted. The bleeder valve must be at the top position when fitted.

—

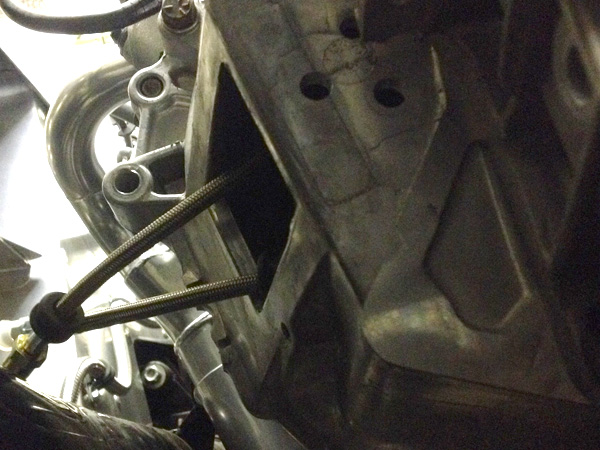

Getting the transmission back in was a bit of a fiddle, while feeding the lines through the old fork hole opening in the bell housing. It is important to check that these lines do not make contact the spinning clutch and flywheel when the engine is running.

—

—

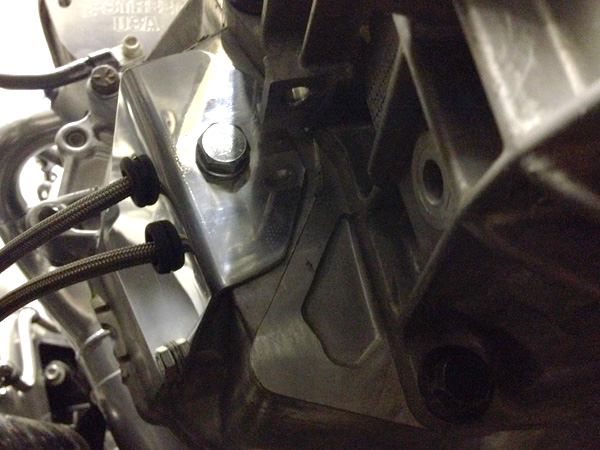

We were mindful of the fact that we needed to protect these 2 lines so we decided to finish of the job by making a simple plate that would cover the opening in the bell housing where the original clutch fork protruded and have the 2 lines pass through this plate, using 2 grommits to protect them from potential chafing. The bellhousing had 2 holes on the back and side that were close to the opening that would be ideal to bolt into to secure a plate to the outside. Firstly we had to tap a thread into these holes. The holes were different sizes, we put a 10mm bolt on the back side, with a 6mm bolt on the side.

—

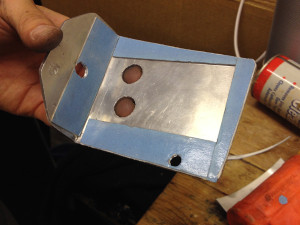

We then made up a simple cardboard template to shape and marked the 2 places where the 2 securing bolt hole would be. Once confident we had is right we marked it up and cut it out in aluminium sheet. We then bent it to shape using the vice while continually checking the shape against the side of the bellhousing. It took a bit of time to get this right. Once we had is correct we finally marked up and drilled 16 mm holes for the 2 lines to pass through. Although this plate will be mostly out of sight we decided to give it a quick polish as well.

—

Before the final fit we decided to use double sided rubber foam on the back side of the plate to create a good seal between the plate and the bellhousing, while also to prevent any unnecessary rattling that may occur.

—

—

We are really happy with the final fit. We think its a really tidy solution. Not only do we believe that using the “Throw out bearing clutch release” will give us a more responsive clutch but we have managed solve the clearance problems we had with the original slave cylinder and the clutch arm.

—

Leave A Comment