We decided we’d really like to get the Cobra started before we get the body back on.

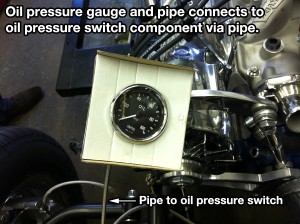

First job was fitting the oil Pressure gauge to the end of the pipe which runs to the adaptor that we fitted to the oil pressure switch out let in the engine block a few weeks ago (Read about that here). Then we connected up the fuel filter and fuel pressure regulator and the fuel line to the carburettor. Next we fitted the oil filter and fill the engine and gearbox with oil.

Before we fitted the distributor we connected a drill to the oil pump drive through the distributor hole and with the drill running in reverse we drove the oil pump and primed the engine. Also now that we had the oil pressure gauge connected we could make sure the pump could produce oil pressure before starting the engine.

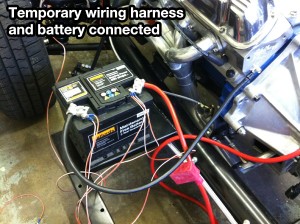

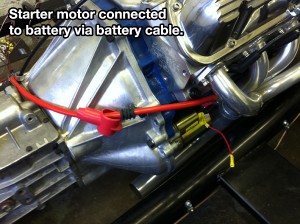

Next thing was to fit the distributor, coil and the ballast resistor to do this we made a temporary wiring harness. We went for a Hall Effect distributor which does away with the points and condencer. See next post (Starting the Engine – Part 2) for fitting the distributor.

—–

Leave A Comment