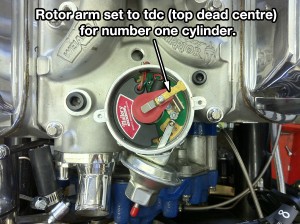

We were then onto fitting the distributor. We fitted the rotor arm to be TDC (top dead centre) for number one cylinder. See diagram for the configuration of distributor cables to cylinders.

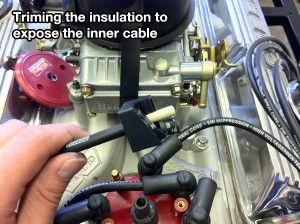

Next was to route the leads, chop them to length, fit them neatly on the spark plugs and then fit onto the distributor cap. We also labeled each lead in turn with the corresponding cylinder numbers. Eventually we will heat shrink the number labels once we have fully timed up the distributor with timing light. We have decided to fit a ballast coil and this requires a ballast resister to be used. This is wired in to the positive side of the coil and reduces the voltage going to the coil which keeps a more stable voltage when the engine is running.

—

Leave A Comment