This is something we did a few weeks ago, but haven’t written it up until now. Original we had some real problems getting the exhaust manifold bolts in and tightened up (read post here).

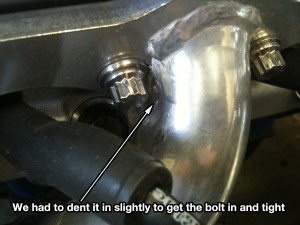

As a possible solution we had sourced some 6 sided bolts from the US in a hope that we could use these and get them on with a simple open ended spanner, but when they arrived we realised the bolt heads were even bigger than the 12 points we already had, so wouldn’t fit. We concluded at this point, the only real option was to take the plunge and to dent the exhaust branches. It wasn’t something we original wanted to do because we were wary of damaging the ceramic coating, but in the end we decided we didn’t have a choice in the matter.

So Mark heated up the problem areas to be dented with a blow torch to get the metal more malleable, then he carefully used a hammer and punch to dent in and create enough space for the bolt heads. The ceramic coating has stood up reasonable well but is slightly damaged in places. It’s something we are going to have to live with at the moment I suppose, although we may see if we can get the coating touched up at a later date.

—

Leave A Comment