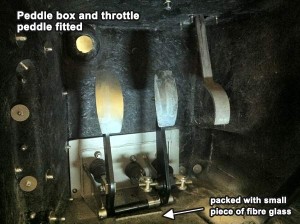

We started today thinking it was about time we fitted the pedal box. As we had already cut the hole in the footwell ages ago, its a job we could now do as the body is back on. The bolts go through the floor and flat section of the chassis and it was just a case of lining it up, marking up and then drilling the holes through. As the end of these bolts are exposed under the car, Mark had bought some stainless steel M8 bolts for this job, so they won’t corrode when exposed to the weather. Due to its position it proved a bit awkward getting these in and getting them tight. Mark bumped his head on several occasions while he had his head stuck down the footwell trying to get the bolts in (Hopefully knocked some sense in). We had noticed before hand that the floor of the body wasn’t quite square so we had to use a small piece of fibreglass, that we saved from cutting the original hole, to pack the front edge, getting a good seal between the vertical edge and engine bay.

Next up was to negotiate the position of the throttle pedal. The throttle pedal is posted through a hole in the top of the pedal box with the throttle pedal housing mounted on top inside the engine bay. We read through the Hawk manual and it didn’t really give any hard and fast rules for the position, although when we had spoken to Gerry at the NEC he told us to aim to mount it about an inch from the front of the pedal box. So this is what we aimed for. We initially drilled a small hole posted the pedal through to get a rough position. We wanted the accelerator pedal slightly further forward than the brake and clutch pedals but for all 3 pedals to be equally spaced apart. From there we marked up the holes, drilled and fitted. This was also a bit fiddly due to it being under the wing and had to use a 90degree drill bit for this job.

—

Leave A Comment