Having taken receipt of the engine a few weeks ago we both put a weekend aside to start building the engine.First job was to crank the engine block up and connect it to an engine stand to allow us to work on it. As all the bits are brand new, things went together fairly quickly.We started by fitting the inlet manifold using the correct gaskets and high temperature silicon and then also fitted the rocker covers using liquid gasket and cork gaskets.

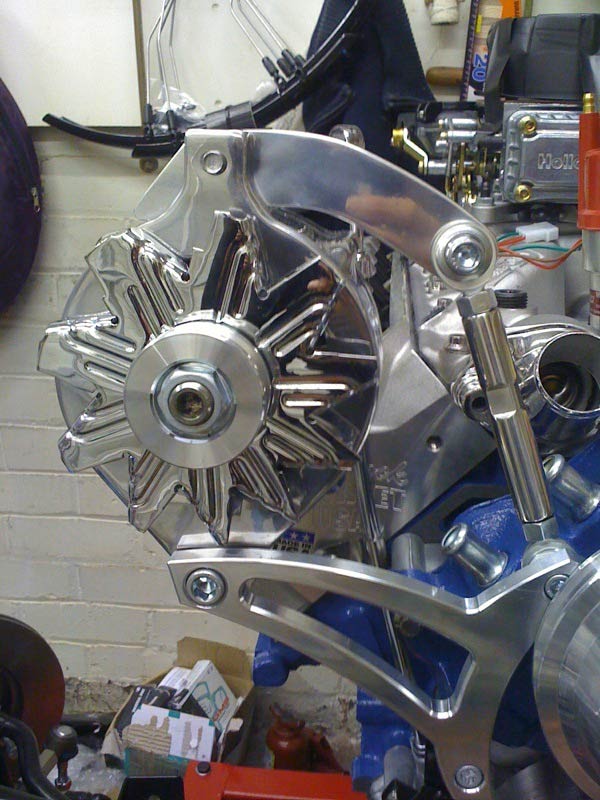

Next came the water pump and alternator. Once we installed the alternator, we discovered a small problem. Firstly we had installed the alternator lower down on the near side of the engine using the bracket provided. This would be ok on some other car models, but we realised that due to the position of steering rack on our cobra that once the engine was in that this alternator position would conflict with the steering rack. We were keen to use as many of the original brackets as possible so after a bit discussion came up with the solution. It would mean making a small aluminium bracket to enable us to mount the alternator up high on the near side.

We managed to get a piece of aluminium from our uncle Dave, (a very handy bloke to know when built a kit car). Mark then cut out the required shape based on a cardboard template. When drilled, polished it up and mounted it to the engine it looked spot on. Job Done!

Hi guys

Just thought someone should say thankyou for all the effort you’re going to in sharing your build with others. Keep up the good work and carry on!!

Colin