Mark has been busy over the last week or so getting things welded and made. This included the coolant pipe to link the radiator to the header tank and also the heater matrix pipes that will connect from the back of the heater box to the inlet manifold. Both pieces we had made custom hand and welded to our measurement from the car.

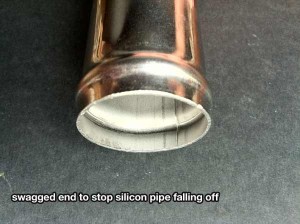

For the coolant link pipe we sourced some 1″3/4 stainless steel pipe. We looked into getting this bent to the 90 degrees we required but unfortunately the radius of the bend would be too great. So we opted to use a 90 degree short elbow, butt welded, and make up the pipe from this. Mark cut the two piece longer than needed before he welded them to the short elbow. After this he cut it to length as well as swaging the ends of the pipe to prevent the silicon pipe slipping off once they are fitted. From this we can now do a temporary fit using some silicon pipe off cuts we sourced. We intend to measure up and eventually get some vintage looking silicon hose for the final fit.

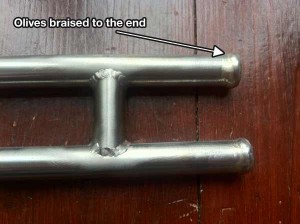

As for heater matrix pipe, Mark got some 16mm diameter stainless steel pipe and made up all the bits by cutting to length and bent one into the correct position to fit nicely onto the inlet manifold coolant outlet. We could then get them welded together. At this point we also got the stainless steel olives braised on the end to create a lip. This again to prevent the silicon hose coming off when its connected.

—

Leave A Comment