We decided to get on with installing the brake pipes. We ordered the brake pipe kit from Gerry with the Hawk kit containing all of the pipe and fittings. The build manual shows the rough route for the pipes.

Running the pipe in

First thing was to run the pipe down the offside of the chassis. We fitted rubber grommets into the ready made holes in the outrigger and piercing holes through them as we ran the pipe through. We then carefully measured the postions for the P-clips to hold the pipe, 7.5 inches apart. We then drilled the holes and used galvanised self tapping screws to secure them. P-clips are provided in the kit to suit the 3/16” pipe. We actually found there wasn’t quite enough in the pack, so we had run around town looking for a place that sold them in this size. In the end Halfords had some.

Connecting the rear calipers

Then we had to connect the pipe to the rear calipers, running the pipe carefully into place. This took a little time and was a bit of a fiddle, connecting and then disconnecting again to get the bends in the pipe just right. We bent the pipe carefully using our hands, ensuring that the pipes didn’t get kinked, but once we had the rough shape we used a vice to get the bends really neat and tidy. We also used a flaring tool to flare the end of the pipe that fit inside the brake pipe unions.

Connecting up the front calipers

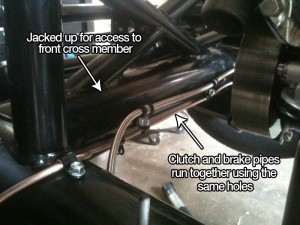

Next was to run the front brake lines in. We started by fitting the front 4 way adaptor. This is held on by the small threaded bar that comes welded to the chassis. There is one on both sides of the chassis depending on it being a RHD or LHD car. The offside one is used for RHD cars. We secured it in place with a M6 nut. We then put the flexi hoses in, connecting the front calipers to the 4 way adaptor via a short piece of brake pipe (flaring both ends). The offside was quite easy to connect BUT running the brake pipe around to the nearside proved to be a bit more difficult as the engine was in the way. So we jacked the chassis up onto axel stands to gain access to the front cross member from underneath. In hindsight, this would have been easier to do before the engine was installed, but nevertheless we got there eventually. We actually used the same holes to mount the clutch pipe brackets at the same time making the final job very neat and tidy.

We won’t be able to connect the whole system up yet until the body is back on and the master cylinders pedal box are installed but we have done most of the work now.

——-

Leave A Comment