—

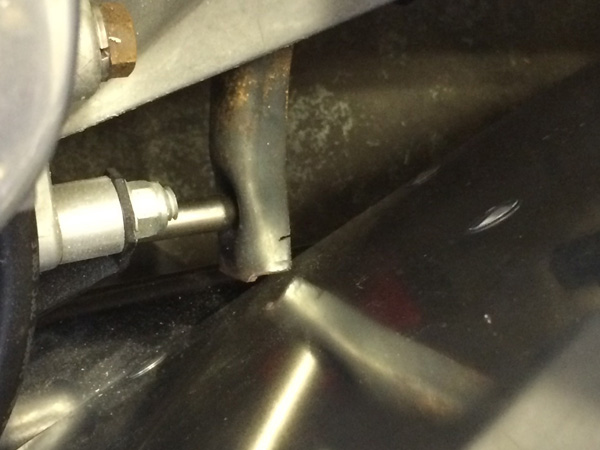

There was a little problem that we have needed to sort. That was namely the clutch fork. We realised a while ago when we got the body back on that the clutch fork was way too close to the body to allow it to work. It had already been shortened by Gerry when we bought the kit but it was obvious there was not enough space for it to work.

—

Word of warning/advise for anyone building a Hawk kit with this clutch specification. Before you get the body back on check the measurements and the space you have for the clutch fork, as modifying it before the body is back on would have been easier in our case.

—

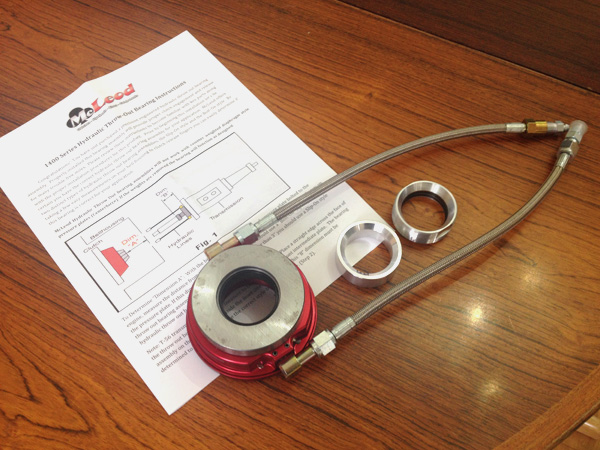

We had tried to get at it with a hacksaw to cut it down but after a few attempts we realised this was a pig of a job to get too and wouldn’t be a nice finish even if we did manage to shorten it. We weren’t happy with this clutch release, so Mark decided to go off to do some research about other clutch release methods that might more suitable. Although perhaps not as authentic, we thought that a hydraulic throw back bearing assembly might be a good upgrade which would allow us to ditch the whole clutch slave cylinder and be a much tidier job. We spoke to Real Steel and they suggested a McLeod Slip-On style assembly that would fit our T5 gearbox and clutch.

—

Leave A Comment