We decided it would be a good idea to make a couple of extra panels around the base of the dash and door support frame to finish things off nicely in preparation for the carpeting. These panels would give a backing for the carpet inside the footwells and we felt would give a better finish when the carpet is fitted. Before the carpet goes in, we also thought that we might try packing foam in between the panels and the body to further the sound deadening effect and adding to a more solid feel around the doors.

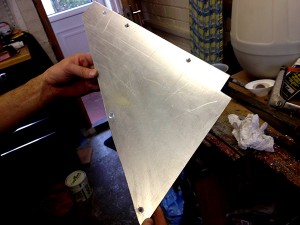

We firstly made some templates from card, before cutting them out to size in 4mm aluminium sheet. We decided to countersink the bolts to achieve a flush fit in order to avoid seeing any fixing through the carpet and to avoid any potential uneven carpet wear in the future. We decided to use riv-nuts as a easy way to secure in place, so after a few small final adjustments we drilling the frame, inserted the riv-nut and finally bolted in place.

We firstly made some templates from card, before cutting them out to size in 4mm aluminium sheet. We decided to countersink the bolts to achieve a flush fit in order to avoid seeing any fixing through the carpet and to avoid any potential uneven carpet wear in the future. We decided to use riv-nuts as a easy way to secure in place, so after a few small final adjustments we drilling the frame, inserted the riv-nut and finally bolted in place.

Hi – glad to see you’re making progress again! Everything went a bit quiet since the May posting. Keep up the good work. I’m awaiting delivery of my Hawk 289, so am following your progress with great interest.