Next up is the Windscreen wipers. We had already drilled and fitted the wheel boxes (you can read about this post here) but we had to fit the motor and driver cable. Originally we used wooden blocks to temporarily mount the wheel boxes at the correct angle but as part of the motor kit we also sourced rubber spacers that sit underneath the body to replace these wooden blocks which are a much neater solution.

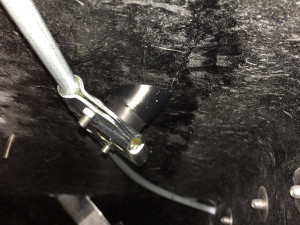

Firstly we assembled the whole motor mechanism running the cable through the bundy tube and wheelboxes. It is important to ensure that the window wiper rack is well greased before it is all assembled. The drive cable that connects the motor to the motor boxes sits inside bundy pipe. The 3 sections of pipe all came as part of the kit and were cut to the correct length with the ends already flared to fit.

The motor is designed to be positioned on the top of the passenger footwell with the driver cable running through the bulkhead and behind the dash. It is important to ensure that the bend in the bundy pipe is sufficient enough to pass through the bulkhead but not severe enough to impact the motion of the cable inside. This means positioning the motor unit at an angle and quiet far underneath the wing. We drilled one hole through the bulkhead for the bundy pipe and gentle bent it to shape before connecting it all up to mark and drill the motor mounting holes in the top of the passenger footwell. It’s virtually impossible to measure everything accurately to find the final position and drill the holes before hand.

Leave A Comment